PJ and a number of other Hive members have been fortunate enough to participate in preparations for the Drexel Design Futures Lab “Projects 12/13” exhibition. PJ was almost certainly the most involved Hive contributor — he helped with the development of a number of key software elements for several of the exhibits.

I had grown some fairly large sheets of bacterial cellulose in the past, and was interested in having an excuse to grow something even larger — so sign me up! Tashia wanted a sheet that started out about 4’x8′ so that the final screen could be cropped to dimensions that were about the size of a slightly gigantic person.I wound up getting involved in the creation of a special display screen that was part of an interactive piece which allows people to “play” with a computer model of bacterial swarms. This piece was part of Tashia Tucker’s exhibit, and she wanted an “organic looking” display surface. After some brainstorming that included condemnations of the high price of silicone etc., PJ suggested bacterial cellulose. What!? The idea of a movie screen made by real bacteria to show movies of simulated bacteria was too “meta” to pass up.

Yikes — this was literally a tall order. Bacterial Cellulose (BC) is created by the same organisms that are used to ferment Kombucha — in fact, the “Shroom” or “Scoby” in a Kombucha culture is a big lump of cellulose. So this was simple, in principle, but the scale of the piece left a lot of novel details that had to be worked out.

Continue reading “Drexel Design Futures, Bacterial Cellulose (and a world record, maybe?)”

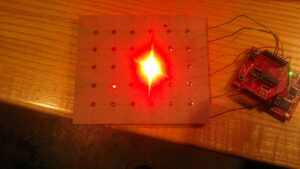

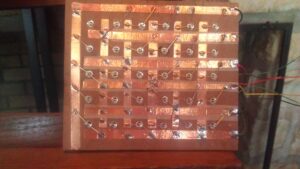

This 5×6 LED tile is a key component in a secret project that I’m developing (in secret) with some other folks (whose names shall remain a secret).

This 5×6 LED tile is a key component in a secret project that I’m developing (in secret) with some other folks (whose names shall remain a secret). You need to flip the tile over in order to see what’s special about it. Here’s a quick list of features that make the assembly what it is:

You need to flip the tile over in order to see what’s special about it. Here’s a quick list of features that make the assembly what it is:

Been reading

Been reading