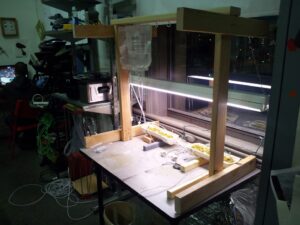

Our old Makerbot case sitting in the scrap parts bin has been resurrected as a grow case for my terrariums! All it took was an afternoon, some scrap plastic sheets, a few LED strips + power supply, and liberal use of a hot glue gun.

Our old Makerbot case sitting in the scrap parts bin has been resurrected as a grow case for my terrariums! All it took was an afternoon, some scrap plastic sheets, a few LED strips + power supply, and liberal use of a hot glue gun.

On Tuesday April 28th Chris Anderson will be instructing a lecture and demo on Hydroponic and Aquaponic gardening. If you are interested in learning alternative farming and gardening techniques this class will introduce a more environmentally friendly process for growing your own produce. Generally, the hydroponics approach is beneficial because although the initial costs are higher, on a long term outlook the process is exponentially less expensive. Hydroponics also takes up to 50% less land use, therefore is much less intrusive to the environment, minimizing clearing of woodlands and soil degradation. The soil-less process of hydroponics also uses up to 90% less water and up to 60 % less fertilizer and pesticide use.

On Tuesday April 28th Chris Anderson will be instructing a lecture and demo on Hydroponic and Aquaponic gardening. If you are interested in learning alternative farming and gardening techniques this class will introduce a more environmentally friendly process for growing your own produce. Generally, the hydroponics approach is beneficial because although the initial costs are higher, on a long term outlook the process is exponentially less expensive. Hydroponics also takes up to 50% less land use, therefore is much less intrusive to the environment, minimizing clearing of woodlands and soil degradation. The soil-less process of hydroponics also uses up to 90% less water and up to 60 % less fertilizer and pesticide use.

Join Hive76 members to learn more about how you can build your own sustainable farming/ gardening hydroponic or aquaponic system. The instructor will be providing the Basic items for the wicking system being built but please bring any supplies you have that may enhance the design. Chris Anderson will help guide the class in how they can optimize their gardening system with their suggested materials, exploring the creative possibilities in using recycled products. That class will cost $8, CASH ONLY. For more information check out the class in the Hive76 Calendar. Please comment below if you are interested and will be attending. Can’t wait to see you there!

Take a tour of Chris Anderson’s classroom design.

The materials for the class are as follows:

PJ and a number of other Hive members have been fortunate enough to participate in preparations for the Drexel Design Futures Lab “Projects 12/13” exhibition. PJ was almost certainly the most involved Hive contributor — he helped with the development of a number of key software elements for several of the exhibits.

I had grown some fairly large sheets of bacterial cellulose in the past, and was interested in having an excuse to grow something even larger — so sign me up! Tashia wanted a sheet that started out about 4’x8′ so that the final screen could be cropped to dimensions that were about the size of a slightly gigantic person.I wound up getting involved in the creation of a special display screen that was part of an interactive piece which allows people to “play” with a computer model of bacterial swarms. This piece was part of Tashia Tucker’s exhibit, and she wanted an “organic looking” display surface. After some brainstorming that included condemnations of the high price of silicone etc., PJ suggested bacterial cellulose. What!? The idea of a movie screen made by real bacteria to show movies of simulated bacteria was too “meta” to pass up.

Yikes — this was literally a tall order. Bacterial Cellulose (BC) is created by the same organisms that are used to ferment Kombucha — in fact, the “Shroom” or “Scoby” in a Kombucha culture is a big lump of cellulose. So this was simple, in principle, but the scale of the piece left a lot of novel details that had to be worked out.

Continue reading “Drexel Design Futures, Bacterial Cellulose (and a world record, maybe?)”

The spinach I was growing managed to complete most of its life cycle. Around a week after my last post I added the nutrient solution to the plants’ water, thats when they really started to take off. I had one hiccup during the test run where I didn’t properly sent the flow rate of one the IV bags and half the nutrient solution was lost. If I was a little less… well lazy that day… I would have replaced it , but I didn’t. So the IV bag ran out of nutrient solution and some of the plants died before they reached maturity. Luckily, the rest of the plants managed to reach their flowering stage. So overall, the IV bags were incredible useful. Thanks Jordan for the idea!

Seeing how classes are starting to pick up, I figure now is a good time to stop the experiment and take some time to look over my notes. But, I hope to have another prototype built by the end of next month. ( Btw, sorry for not being around open house lately to discuss hydroponics, I have a night class that meets at the same time this semester).

Speaking of which, a friend of mine who frequently stops by open house, Ian, has taken the plans of the hydroponic garden I built two years ago and built one of his own at home. Suffice to say, the plants have grown wild and are firmly in control of his bedroom. Given how successful his garden has been, he’s inspired me to dust of my old plans and think about building another, LARGER, set up for just for show (the hydro setup currently at Hive is mainly for experimentation). That’s all for now…

So here is a quick update on my hydroponics setup at Hive76. In my previous post I uploaded a video on a hydroponic garden I built in my basement two years ago. My goal was to build the setup with as little moving parts as possible to ensure the garden required little maintenance. With the hydroponic garden I am building at Hive76 I decided to keep to the spirit of simplicity but a completely different approach with it.

With my latest version I am using medical grade IV bags to store the water above the plants. Then by attaching a mechanism to the IV bags known as a ‘flow controller’, gravity pulls the water from the bags to the plants below at a consistent rate. The rate at which water flows through that controller be anywhere from 5 to 250 ml / hr.

The IV bags and flow controllers are great because they are very inexpensive (one IV bag and flow controller cost me a few dollars from medtecmedical.com). Plus they can potentially be reused since they are being used on plants and not humans if you are careful to prevent contamination. But possible the most useful thing about using IV bags is that they require no energy to operate, which further reduces costs.

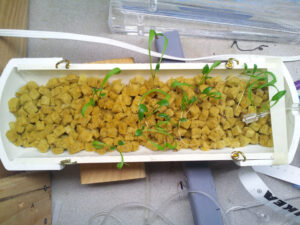

To evenly distribute the water that is supplied by the IV bags to the plants, I put the plants within a medium of rockwool cubes that are about 1 cubic centimeter in size. The rockwool essentially acts as a sponge that takes the water that is supplied by the IV drip and evenly distributes it to all the plants within the container.

I’m testing my current hydroponic setup on spinach seeds at the moment. The plants are still in their infancy so I have not added nutrients to their water supply yet but I plan to do so in about a week(adding too high a concentration of nutrients to young plants can damage their roots). My short term goal is to monitor the spinach in my hydroponic setup through its entire life cycle, taking general notes along the way. After the plants have finished their life cycle I want to take some time to build a second prototype and post its plans on Hive’s webpage. Hopefully by that point, the system will be a useful platform for scientific experimentation. Then the real fun can begin!!!

My current project at Hive76 is working on indoor hydroponic systems. The project comes from an interest in plants that I picked up from tending to my mother’s garden as a child. My family was fortunate to have enough land for a sizable garden when I was growing up, but now that I live near center city Philadelphia, good plots of land can be difficult to find. So I naturally turned to hydroponics because it is not limited by land area the same way that traditional farming is.

Hydroponics has the potential to revolutionize farming as we know it because it allows for plants to be grown in highly controlled environments. This means that the light, water, and nutrients that plants need to thrive can be optimized to promote rapid growth while reducing waste and pollution. Also, as mentioned before, hydroponics systems be built vertically instead of just horizontally, which is a huge benefit in dense urban environments like Philadelphia.

Even with all the potential benefits of hydroponics, it has yet to become a competitor with traditional farming in the open market. There are many reasons for this, one reason is that the cost of lighting in an indoor hydroponic system will always cost more than traditional farming, which gets its light for free from the sun. (Luckily the cost of lighting is dropping all the time with advancements in florescent bulbs and LED technology.) Another reason is that there is a lot of politics around farming that doesn’t favor the development of hydroponics.

Despite all the this, hydroponics is still holds a lot of potential to revolutionize agriculture. It is also a great way to learn about plant science. I’m particularly interested in using hydroponics to develop a low cost platform for amateur science experiments. The hope is that by empowering people with the right tools , the next breakthrough in agriculture might come from a high-school student’s science fair project!

The hydroponic system that I am building at Hive76 is very much in the early stages. In the meantime, I wanted to post a video on a previous hydroponic system that I built in my basement 2 years ago. It works by flooding the roots of the plants with water supplied by a reservoir below.

Enjoy and stay tuned for updates!

Back in mid September, we made a batch of Bacterial Cellulose in two 44″ x 18″ tray bioreactors, using Adam Korshid’s “blanco cellulose” medium (sugar, yeast and apple-cider vinegar in ratios carefully measured by eye and tongue). About two weeks later, one of the cultures had essentially failed, but the other had blossomed with a vengeance, coughing up a giant, off-while pellicle that was about 3/8 inches thick and probably weighing a good 10 pounds. For what it’s worth, it was also quite a smelly beast. In fact, the smell largely motivated the timing of the harvest (kind of a “get-that-friggin-thing-outta-here” situation). One unexpected benefit of the stench was that I was able to identify butyric acid as the main offender — so the absence tea in the culture seems to result in increased butyric acid production. Possibly a consequence of the low nitrogen content of the “blanco” medium? It might be interesting to research the topic …

At any rate, the 44×18 sheet was ultimately dried and delivered to Ann Saintpeter as promised. We’ll see what she prints on it, if anything. While the sheet was drying, I discovered that you could kill the smell by dusting it with baking soda. It also turns out I was late to that particular party — apparently baking soda is renown as an odor killer precisely because it forms salts with organic acids that tend to be some of the main components of many unpleasant odors.

The sheet ultimately dried to look very much like a giant, soft tortilla, complete with a dusty surface (courtesy of the baking soda). It also ended up with some mild scorch marks, since I was trying to dry it in a hotel room, using the courtesy hair-dryer and iron. If nothing else, the scorch marks helped with the tortilla-like appearance.

I’m currently embarking on a little experiment to study factors influencing cellulose production, including density of the substrate (i.e. how much sugar to hit the production “sweet spot”, so to speak) and substrate type (supposedly glycerin is the ultimate feed-stock). If there are any results worth publishing, we will do so — possibly with hardcopies on microbial cellulose paper.

As mentioned previously, on Sunday, the 5th of September, members of Hive76 spent time cleaning up the street at 915 Spring Garden St. The work proved to be hard but rewarding. While there are still significant areas of garbage and weeds, we made a big impact on the areas in which we worked, paving the way for future improvements.

As the coordinator for this particular activity, I really want to give my deepest thanks to our members Mike Hogan, PJ Santoro, and Dan Toliaferro for coming out and busting their asses in the 80+F weather. I also want to thank Dave Sharp for providing some supplies as well as one of our fellow tenants at 915 Spring Garden St. for bringing us water while we were working.

More cleanup efforts are still to come, we really want to develop the garden box and maybe add more garden boxes around the building. We’d also like to spiff the place up a little it with some local art, any sort of standing sculptures that can live permanently in our new garden. If you would like to donate to our cause, with plants or dirt or trees or money to buy such things, then please contact us at hive76@hive76.org.

In the meantime, check out the before and after pictures:

The block on which our building for our space sits is a bit of a… wayward soul. There is a lot of garbage tumbleweeding through the street, giant weeds poke up through the sidewalk everywhere, and a smattering of graffiti makes someone’s presence known.

Well, we’ve decided to clean it up. All of it. Next Sunday, September 5th, from 12pm to 5pm, we’ll meet at the space and just start doing. We originally planned to do it this weekend, but the IMPENDING DOOM NAMED IRENE has forced us to postpone.

Bring what you can, plastic garbage bags, shovels and rakes, brooms, leftover paint, etc. Don’t forget some heavy gloves, there are a lot of broken glass and other sharps in the area.

If you can’t make it to this date but still want to help out, we will have other dates in the near future, so stay tuned to the blog for future announcements.

We here at the Hive are (un?)fortunate enough to have two large windows that don’t seem to want to stay open (read: safety hazard). What are we supposed to do with stuff that doesn’t work the way it should? Use it for something else, of course!

We are looking to increase some of our greenery and reduce our grocery bills by growing food and herbs at the space. Now, with your pizza or burrito, you can enjoy a fresh picked geek salad!

Though the build specifics(?) still need to be hashed out, you can be sure to see some plants in our 5th story windows this spring.